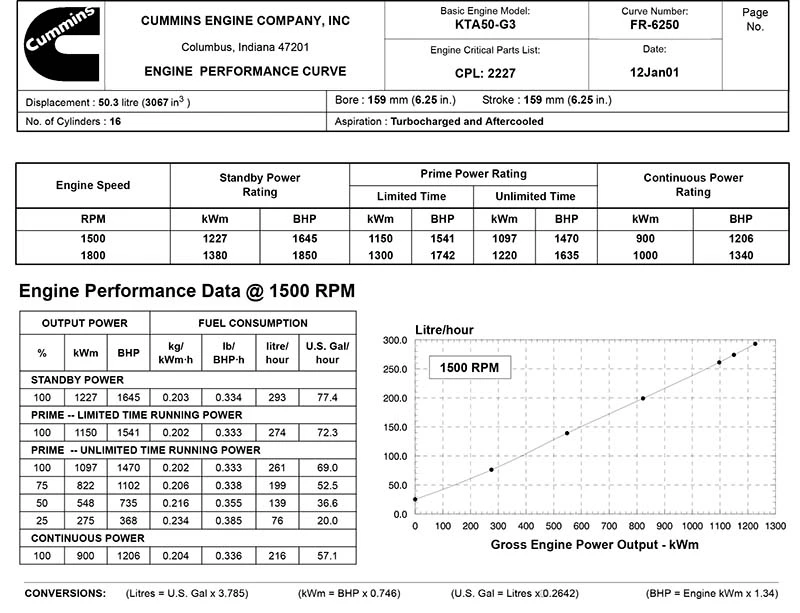

Cummins 1 MW diesel generator Fuel Consumption Chart

The Cummins 1 MW diesel generator is powered by a Cummins engine KTA50-G3. It has a special enclosure to reduce noise in any weather, keeping it at 88db at a 7m distance. It also has a built-in fuel tank so you don’t have to refuel often, using less than 262L/h of fuel consumption. An AVR guarantees stable power and has safety features like automatic shutdown for low oil levels or other problems.

POWER OUTPUT:

1100KW (1375 KVA) STANDBY, 1000KW (1250KVA) PRIME, 3PHASE, 0.8PF, 50HZ

Datasheet of Cummins 1 MW Diesel Generator

- Genset Supplier – METCL

- Genset Model – C1375GF/S

- Generator Speed – 1500 RPM

- Displacement – 50.3 Litre

- Fuel Consumption at rated 1000kW/1250KVA Load- 262 Litre/h

- Cummins Engine KTA50-G3, 1227kW, 1500RPM, Turbocharged

- Electronic Speed Governor

- Radiator cooling system with fan guards and coolant drain extension with in-line valve

- AC Alternator Producer – STAMFORD/Leroy-Somer/Mecc Alte

- AC Alternator 4 Leads, brushless, 100% Copper Windings

- Full load rated Power – 1000kW/1250kVA

- 50 Hz. 1500RPM 3Phase AC400V

- 3-Phase AC380/415/440V etc Multi-voltage as optional

Features of Cummins Engine KTA50-G3

Cummins engine KTA50-G3 is recognized for its performance, reliability, and durability worldwide. With its very high derating threshold for temperatures, altitudes, and humidity, the Cummins KTA50 G3 engine ranks among the top performers in the harshest operating environments.

Cummins 1 MW diesel generator Fuel Consumption Chart

GENERAL CUMMINS KTA50-G3 ENGINE DATA SHEET

Type ………………………………………………………………………………………………………………….. 4-Cycle; 60° Vee; 16-Cylinder Diesel

Aspiration…………………………………………………………………………………….. …………………….Turbocharged and Aftercooled

Bore x Stroke………………………………………………………………………………………………..— in x in (mm x mm) 6.25 x 6.25 (159 x 159)

Displacement……………………………………………………………………………………………………….. — in3 (liter) 3067 (50.3)

Compression Ratio…………………………………………………………………………………………………13.9: 1

Dry Weight

Fan to Flywheel Engine……………………………………………………………………………………………. — lb (kg) 11820 (5360)

Heat Exchanger Cooled Engine……………………………………………………………………………….. — lb (kg) 12260 (5560)

Wet Weight

Fan to Flywheel Engine……………………………………………………………………………………………. — lb (kg) 12485 (5662)

Heat Exchanger Cooled Engine…………………………………………………………………………….. … — lb (kg) 13085 (5934)

Moment of Inertia of Rotating Components

- with FW 6009 Flywheel ……………………………………………………………………………… — lbm • ft2 (kg • m2) 301 (12.7)

- with FW 6017 Flywheel ………………………………………………………………………………. — lbm • ft2 (kg • m2 ) 515 (21.7)

Center of Gravity from Rear Face of Flywheel Housing (FH 6024)…………………………………. — in (mm) 47.5 (1206)

Center of Gravity Above Crankshaft Centerline…………………………………………………………….. — in (mm) 11.0 (279)

Maximum Static Loading at Rear Main Bearing……………………………………………………………….. — lb (kg) 2000 (908)

ENGINE MOUNTING

Maximum Bending Moment at Rear Face of Block………………………………………………… — lb • ft (N • m) 4500 (6100)

EXHAUST SYSTEM

Maximum Back Pressure @ Standby Power Rating……………………………………………. — in Hg (mm Hg) 2 (51)

AIR INDUCTION SYSTEM

Maximum Intake Air Restriction

- with Dirty Filter Element @ Standby Power Rating ……………………………………… — in H2O (mm H2O) 25 (635)

- with Clean Filter Element @ Standby Power Rating……………………………………. — in H2O (mm H2O) 15 (381)

COOLING SYSTEM

Coolant Capacity — Engine Only……………………………………………………………………….. — US gal (liter) 42.5 (161)

Maximum Coolant Friction Head External to Engine

— 1800 rpm…………………………… — psi (kPa) 15 (103)

— 1500 rpm…………………………… — psi (kPa) 10 (69)

Maximum Static Head of Coolant Above Engine Crank Centerline……………………………………… — ft (m) 60 (18.3)

Standard Thermostat (Modulating) Range……………………………………………………………………… — °F (°C) 180 – 200 (82 – 93)

Minimum Pressure Cap (For Cooling Systems with less than 2 m [6 ft.] Static Head)…….. — psi (kPa) 14 (96)

Maximum Top Tank Temperature for Standby / Prime Power …………………………………………. — °F (°C) 220 / 212 (104 / 100)

LUBRICATION SYSTEM

Oil Pressure @ Idle Speed………………………………………………………………………………………. — psi (kPa) 20 (138)

@ Governed Speed …………………………………………………………………………….. — psi (kPa) 50 – 70 (345 – 483)

Maximum Oil Temperature……………………………………………………………………………………………. — °F (°C) 250 (121)

Oil Capacity with OP 6024 Oil Pan : High – Low …………………………………………………….. — US gal (liter) 40 – 32 (151 – 121)

Total System Capacity (Including Bypass Filter)…………………………………………………….. — US gal (liter) 46.7 (177)

FUEL SYSTEM

Type Injection System………………………………………………………………………………………….. Direct Injection Cummins PT

Maximum Restriction at PT Fuel Injection Pump — with Clean Fuel Filter…………………. — in Hg (mm Hg) 4.0 (102)

— with Dirty Fuel Filter………………………………………… — in Hg (mm Hg) 8.0 (203)

Maximum Allowable Head on Injector Return Line (Consisting of Friction Head and Static Head)……. — in Hg (mm Hg) 6.5 (165)

Maximum Fuel Flow to Injection Pump……………………………………………………………………. — US gph (liter / hr) 165 (625) ELECTRICAL SYSTEM

Cranking Motor (Heavy Duty, Positive Engagement)……………………………………………………. — volt 24

Battery Charging System, Negative Ground …………………………………………………………………..— ampere 35

Maximum Allowable Resistance of Cranking Circuit………………………………………………………. — ohm 0.002

Minimum Recommended Battery Capacity

- Cold Soak @ 50 °F (10 °C) and Above …………………………………………………………………… — 0°F CCA 1280

- Cold Soak @ 32 °F to 50 °F (0 °C to 10 °C)…………………………………………………………….. — 0°F CCA 1800

- Cold Soak @ 0 °F to 32 °F (-18 °C to 0 °C)……………………………………………………………… — 0°F CCA 1800

COLD START CAPABILITY

Minimum Ambient Temperature for Aided (with Coolant Heater) Cold Start within 10 seconds………. — °F (°C) 50 (10)

Minimum Ambient Temperature for Unaided Cold Start……………………………………………………………….— °F (°C) 45 (7)

PERFORMANCE DATA

All data is based on:

- Engine operating with the fuel system, water pump, lubricating oil pump, air cleaner, and exhaust

silencer; not included are battery charging alternator, fan, and optional driven components.

- Engine operating with fuel corresponding to grade No. 2-D per ASTM D975.

- ISO 3046, Part 1, Standard Reference Conditions of:

Barometric Pressure: 100 kPa (29.53 in Hg) Air Temperature: 25 °C (77 °F)

Altitude: 110 m (361 ft) Relative Humidity: 30%

Steady State Stability Band at any Constant Load …………………………………………………………………………— % +/- 0.25

Estimated Free Field Sound Pressure Level of a Typical Generator Set;

Excludes Exhaust Noise; at Rated Load and 7.5 m (24.6 ft); 1800 rpm / 1500 rpm…………………………… — dBA 94.6 / 92.4

Exhaust Noise at 1 m Horizontally from Centerline of Exhaust Pipe Outlet Upwards at 45° — 1800 / 1500 rpm…..— dBA 126 / 125